Project

NELLHI is based on the products of industrial partners. Their drive in the project is to set up a high-quality supply chain that allows each to set their name to an end product that is beyond the state of the art in terms of cost, performance and reliability. To this effect, each industrial partner has set up a production line that will enable large-scale series manufacturing, for which each component will be optimized. One industrial partner is involved for each key function: Elcogen AS (cells), AB Sandvik Materials Technology (interconnector plate material and coating), Borit (interconnector plate manufacturing), Flexitallic Ltd (sealing) and Elcogen Oy (stack design, stack assembly and production). These companies are each focusing on a different stack part and are therefore strongly complementary.

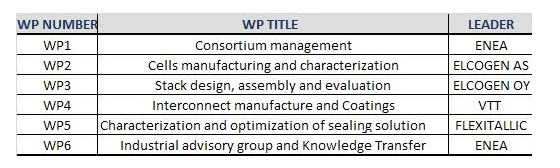

Work Packages

NELLHI consists of six work packages, each managed by a work package leader responsible for the outcome and timing of their work package.

WP 1: This work package is reserved for the management issues of the whole project to ensure that the project progresses according to schedule and research plan.

WP 2: The overall objective of this WP is to up-scale Elcogen’s low-temperature cell to a larger 120x120 mm foot-print. Excellent cell performance is already demonstrated in 100x100 mm size, but within this project, the cell will be up-scaled to a larger size and validated.

WP 3: The aim of this WP is to design, assemble, and experimentally evaluate stacks based on 1 kWel module developed in this project using realistic conditions for stationary applications. This WP integrates results of other WPs into the stack design. The modular stack, validated at around 1 kW power level, will be used to develop and demonstrate a stack module design scalable up to 10 kW power level.

WP 4: This work package supports WP3. Steel rolling and shaping to provide extra thin interconnector plates in mass-production will be combined with the selection of the optimal coating materials and process for the production of pre-coated steel. This material will be shaped in specifically designed dyes for the final interconnects production, scaled up to the larger stack size and designed for mass-production.

WP 5: This WP also supports WP3. Commercial gasket materials will be characterized and optimized in this WP and hybridized glass-compressive gaskets will be developed and tested and the most suitable ones will be used in the stack.

WP 6: The aim of this WP is to boost the transfer of the knowledge and new results developed within the project to targeted audiences, via different dissemination tools, as well as to interact with Elcogen Oy’s potential customers and ensure that customers’ needs are taken into account in the stack design. The Industrial advisory group will help to define boundary conditions for stack design, materials, and manufacturing methods.